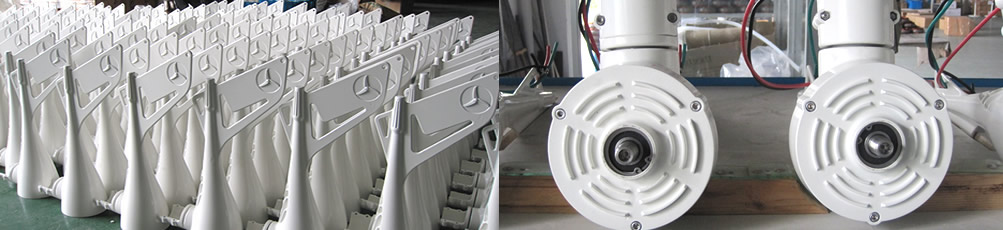

Both the controllers of S-600 and S-700 have the function of switching 12V and 24V freely. The difference between the two is that the 12V system and the 24Vsystem of S-600 adopt the same electrical motor. If you want to change the voltage output system, just turn the 12V&24V switch at the bottom of bady to the place you want. As to the S-700, in order to get the greatest output power, there are difference eletrical motor for 12V system and 24V system. If you want to change the voltage output system, not only turn the 12V&24V switch at the bottom of bady to the place you want, but also change the right electrical motor.

Caution: Whether you use S-600 or S-700, ensure the battery bank, inventer and loads must match with the output voltage when you want to change it.

Note: You can purchase the approciate alternator from your dealer or distributor.

When you want to chage the output voltage of S-700, please ensure to follow the steps below or your alternator will rotate difficultly or even be damaged.

Step1 Turn the 12V&24V switch at the bottom of bady to the place you want. There is a lable marking 12V and 24V at the bottom of body.

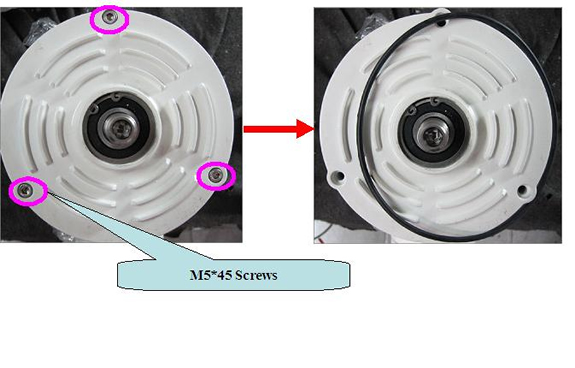

Step2 Unscrew the three M5*45 Screws using a 4mm hex key to open the face carefully and remove the o-ring.

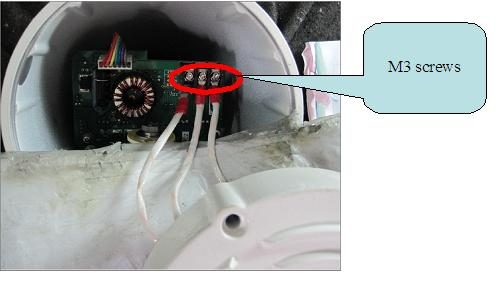

Step3Use one hand or something else to protect the alternator from touching body and use another hand to loosen the three M3 screws on the controller and then you can remove the whole alternator.

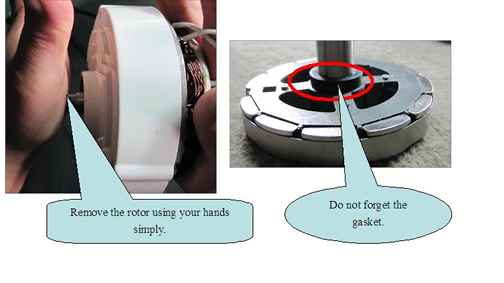

Step4You can remove the rotor using your hands simply and then mount it into the new stator. Do not forget the gasket between rotor and face bearing. Push the rotor to see if it is at the same level with silicon steel sheet.

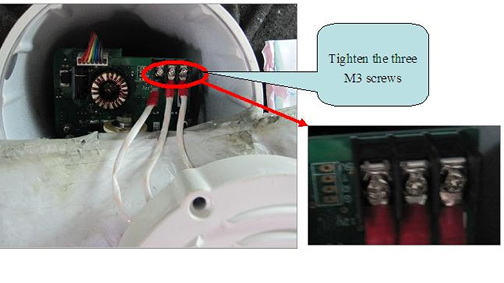

Step5With something else or one of your hands between alternator and the body, insert the three quick connectors on the alternator into the three connectors on the controller arbitrarily as shown below, and then tighten the three M3 screws on the controller.

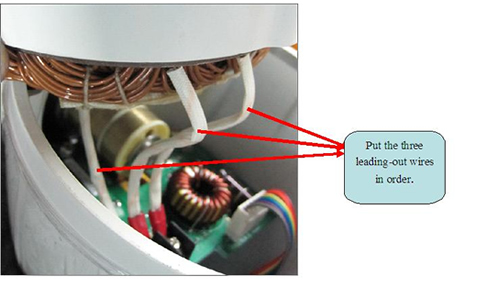

Step6Put the three leading-out wires in order carefully and observe their bending direction to ensure that the leading-out wires do not touch the inside of body, the rotor and the slip ring. If the leading-out wires touch the inside of body, an alternator short circuit will be caused and the alternator will rotate difficultly and can not output current; If the leading-out wires touch the rotor or the slip ring, the leading-out wires will be worn off and can not output current. It will take a long time to diacover the problems.

Step7Close the face and put the O-ring on and tighten the three M5*45 screws. Turn the rotor shaft slightly to see if it is flexible. If not, the alternator leading-out wires must touch the inside of body. You should pull the alternator lightly and put the leading-out wires in order.

Congratulations! You have completed the changing process now.